PLASTIC INJECTION MOLDING

DESIGN FOR MANUFACTURE

Let our team evaluate your part design for optimized production and quality assurance.

Capabilities

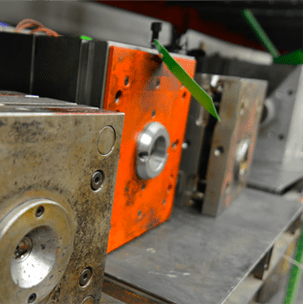

Mold Transfers

SWPC understands it’s a huge undertaking to move or build molds. That’s why we make the process seamless. Transferred molds undergo a full inspection by our engineering and tool room personnel upon delivery into our facility. After your mold is qualified via FAIR or PPAP, we move to production, keeping you in supply of your critical components.

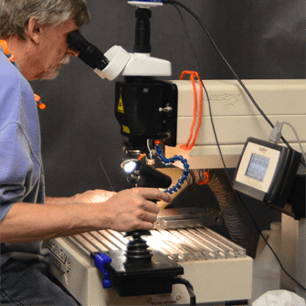

Mold Making & Maintenance

With 30+ years’ experience, a new tool room, and a dedicated team of professional mold-makers and technicians, SWPC can build, maintain and house your molds for the duration of their life. Let our engineering team help you design a better part, cut costs for high-volume projects and refurbish your molding investments.

Over Molding

If your part needs to provide a softer feel, improve grip or protect against impact, over molding rigid plastic with elastomer is the way to do it. With presses available to produce multiple parts for final assemblies, SWPC offers the product you need from a single-source.

Insert Molding

Insert molding provides better strength and longevity to critical components. That’s why aerospace, utilities and firearms companies use this process to make a permanent bond between plastic and metal parts.

Prototyping

Not all projects require production quality molds. SWPC Plastics has the unique capability to produce prototype parts on our SLS machines, as well as manufacture SLS molded inserts. We use these processes for low volume and/or preproduction samples to validate fit, form and function prior to production mold qualification.

Mold Transfers

SWPC understands it’s a huge undertaking to move or build molds. That’s why we make the process seamless. Transferred molds undergo a full inspection by our engineering and tool room personnel upon delivery into our facility. After your mold is qualified via FAIR or PPAP, we move to production, keeping you in supply of your critical components.

Mold Making & Maintenance

With 30+ years’ experience, a new tool room, and a dedicated team of professional mold-makers and technicians, SWPC can build, maintain and house your molds for the duration of their life. Let our engineering team help you design a better part, cut costs for high-volume projects and refurbish your molding investments.

Over Molding

If your part needs to provide a softer feel, improve grip or protect against impact, over molding rigid plastic with elastomer is the way to do it. With presses available to produce multiple parts for final assemblies, SWPC offers the product you need from a single source.

Insert Molding

Insert molding provides better strength and longevity to critical components. That’s why aerospace, utilities and firearms companies use this process to make a permanent bond between plastic and metal parts.

Prototyping

Not all projects require production quality molds. SWPC Plastics has the unique capability to produce prototype parts on our SLS machines, as well as manufacture SLS molded inserts. We use these processes for low volume and/or preproduction samples to validate fit, form and function prior to production mold qualification.